How Do You Control The Flow Rate Of A Dosing Pump?

A dosing pump is a liquid metering pump used to dispense precise amounts of chemicals, such as chlorine or pH adjusters, into a swimming pool or spa. The flow rate of a dosing pump is the amount of liquid dispensed per unit of time, and it can be controlled in several ways to ensure accurate and consistent dosing.

Control the stroke length

The stroke length of a dosing pump is the distance that the pump’s piston moves during each cycle. By adjusting the stroke length, you can control the amount of liquid dispensed per cycle and, thus, the flow rate.

Control the stroke rate

The stroke rate of a dosing pump is the number of cycles the pump completes per unit of time. By adjusting the stroke rate, you can control the flow rate by changing the number of cycles the pump completes.

Control the inlet pressure

A dosing pump’s inlet pressure is the liquid’s pressure at the pump’s inlet. By adjusting the inlet pressure, you can control the flow rate by changing the pressure of the liquid entering the pump.

Control the outlet pressure

The outlet pressure of a dosing pump is the pressure of the liquid at the pump’s outlet. By adjusting the outlet pressure, you can control the flow rate by changing the pressure of the liquid exiting the pump.

Control the diameter of the orifices

The diameter of the orifices on a dosing pump can also be used to control the flow rate. The smaller the orifice, the less liquid can pass through in a given amount of time.

Use a flow meter

A flow meter is a device that measures the flow rate of a liquid. By installing a flow meter on your dosing pump, you can monitor and adjust the flow rate to ensure that the correct amount of chemicals is being dispensed.

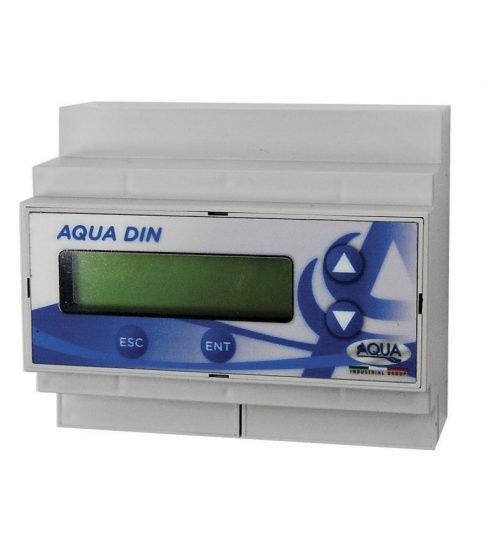

Use a programmable controller

Some dosing pumps have a programmable controller that allows you to set the flow rate and schedule the dosing. This can be a convenient way to control the flow rate and ensure that the chemicals are dispensed at the correct time.